A Painted Birch Triangle Backstool

Construction Notes

Virginia (Black) Walnut

A Painted Birch Triangle Backstool

Construction Notes

Virginia (Black) Walnut

Materials: Birch

Finish: Milk Paint (Salem Red, Marigold Yellow, and Pitch Black) and Linseed Oil

Backpost Height (to tenon): 37-1/2 inches.

Backrest Width: 17 inches.

Seat Height: 17 inches.

Seat Width: 14-3/8 inches.

Seat Depth (back rails): 13 inches.

Front Post Height: 18-1/2 inches.

I found a good price on some large birch timbers, which turned out to be a good thing, because in experimenting with new tools and spindle profiles, I have turned the stool almost twice over.

In designing this piece, I wanted the proportions to be heavier than the ones I'd done previously; my visit to the V&A and the Museum of London showed 16th and 17th turned furniture to be more substantial than I've done so far. A bit of detail from Bruegel captures more the proportions I was looking for (though the style of turned backrest and profiled spindles is from a later period):

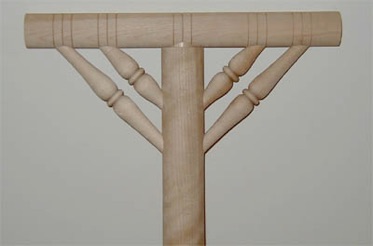

I began by turning the backpost, which is the longest and heaviest part. The backpost ends in a 1-inch diameter round tenon, which fits into the backrest. I then turned the backrest and bored the mortise to receive the tenon. In past projects, I've done most of the detail turning first, and bored the mortises last. I decided this time that it was probably easier to bore mortises while the spindels were still simple cylinders.

My first innovation was to build a boring jig for the drill press; I've conceded that I just don't have the eye-hand skills to bore angled mortises by hand. The result is pictured below; a wooden set screw holds the spindle in place for boring.

The biggest challenge is to get the mortises for the diagonal struts to line up correctly. With the backpost and backrest fitted together, I can then build pattern sticks for the struts.

I then turned the support struts and fitted them to the mortises. When the backrest is assembled it is very snug and needs no glue.

I then turned additional profiles on the backpost and backrest, working carefully not to tear out around the mortises for the struts.

At this point, I proceeded to turn the remainder of the framework (front posts, rails, and seat spindles). Construction from here is the same as for a triangle stool.

I disassembled the piece for painting, which made the details around the rings easier to paint.

In general I found birch not as nice to turn as walnut or cherry, but for the most part it behaved itself. I also learned that when turning a piece for painting, one needs to pay attention to the profile details, leaving room for the brush around rings, etc.

Copyright 2019, Thomas Rettie.